What Is the Reorder Point Formula?

Implement key performance indicators (KPIs) such as inventory turnover rate, days on hand, and service level to evaluate how well your inventory meets customer demand. Utilize inventory management software which one of these would not be a factor in determining the reorder point? to track these metrics in real-time, allowing for prompt adjustments to your reorder point. To accurately calculate reorder points, you’ll need strong sales volume records and trends over a certain period.

- It also factors in goods in transit (GIT), which are products that have been ordered from a vendor but haven’t been received yet.

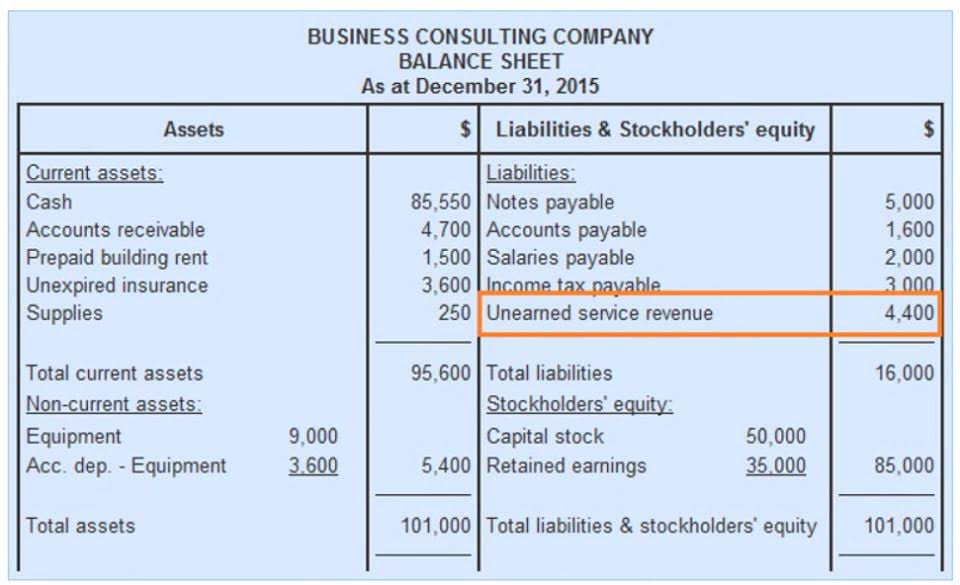

- Inventory represents finished and unfinished goods that have not yet been sold by a company.

- That means that when your inventory falls to 62 lamps, it’s time to order more lamps.

- For this reason, inventory management is a very important part of core operations activities.

- This formula alteration means that replenishment stock will be ordered sooner, which greatly reduces the risk that there will be a stockout condition.

- Now that you know the reorder point formula, we’ll show you how to find your reorder point by going through a sample calculation.

- Optimal inventory levels are those that maximize profit from sales, while minimizing cost from storage, shipping, and working capital deployment.

Safety stock

Keeping your inventory in top shape requires ongoing tweaks and clever thinking. Here are some top tips to help you handle your reorder points like a pro. When your inventory hits the reorder point of 720 units, that’s your cue to place a new order.

Track and manage time

Ask your existing suppliers to see if there’s a way to expedite the process, and if not, shop around to see if there’s someone else who can — without sacrificing quality. Better yet, consider using a just-in-time or material requirements planning system, which only order new inventory when there is a specific, identified reason for doing so. Inventory control is all about ordering just enough product to satisfy demand without tying up cash carrying inventory you don’t need yet. By properly calculating reorder point, your business can place orders confidently and completely, without overspending on inventory that’ll just sit on the shelves. In this article, we’ll define reorder point, reveal how to calculate reorder point, and help you understand how to use reorder point to make your business more profitable and productive. Finally, we’ll also discuss how inventory management software can help you automate reorder point-related tasks.

Calculating average daily unit sales

To help business owners get out of the weeds of manual calculations and processes and get back to big-picture, high-value tasks. To learn more about how SkuVault Core can help you calculate and automate your reorder points across the board, contact our team for a live demo today. Automation does not only save time, but it can also keep your data more accurate. As systems are connected and using the same data points, operations management is more streamlined and efficient. For example, you can set inventory management software to automatically remind you when your inventory dips below a certain threshold. That way, you know exactly when you need to fill out and submit a purchase order without any wasted lead time.

- At the same time, not enough stock causes slow order fulfillment, the potential for missed sales, and lost revenue.

- Customers will simply look elsewhere to buy the product—a process the Internet has made easier than ever.

- If your firm were part of the supply chain for peanut butter products, you would have needed to quickly change your forecasts.

- Therefore, the manufacturer should reorder this component when stock falls to 150 units.

- Then, simply head to a given item’s inventory details, then add the reorder point in the minimum level field.

Over those three months (or 92 days), an average of 1.5 units were sold daily. Not only is the product shortage going to adversely affect the profitably of your company, but it’s going to adversely affect you, too. Because you, as a marketing manager, probably earn either a bonus or commission from the products you work to promote, depending on how well they sell. With features like real-time tracking, optimized routing, and proof of delivery, eLogii helps eliminate uncertainties and boost customer satisfaction. Ordering at the right time ensures you always have items to sell, avoiding delays in fulfilling customer orders. Safety stock is like your backup plan for those unexpected moments—think of sudden rushes in demand or hiccups in your supply chain.

By incorporating these sophisticated software solutions, businesses can automate the reorder point process, gain valuable insights, and enhance overall efficiency and profitability. A company’s ordering cost includes the cost of placing and receiving an order, as well as the cost of the materials. The carrying cost is the cost of storing the inventory, which includes the cost of the space and the cost of the materials. This means that the business should reorder t-shirts when the inventory level reaches 150 shirts. A reorder point is the time when a company needs to restock its supply of raw materials, components, or completed goods. Now let’s plug those figures into the reorder point formula to find your reorder point.

Final thoughts on the reorder point and its importance in inventory management

Improved inventory management can lead to increased revenue, lower handling and holding costs, and improved cash flows. Read this section and explore the fundamentals of inventory management. The benefits to improved inventory management processes are lower costs and improved cash flows. Contemporary inventory management software can streamline this process, minimizing the chance of human error and liberating your time for other essential business activities. Harnessing advanced forecasting techniques is akin to having a sales climate forecast at your fingertips.

Factors that Affect Reorder Point:

So you decide to calculate your company’s drywall anchor reorder point. Reorder point takes more into account than how much of a particular item your business needs. The calculation also factors how long it takes your suppliers to process orders and how long it takes those suppliers to deliver purchases to your receiving department. It’s a balancing act between holding enough stock to meet customer demands and not tying up too much capital in inventory. Suppose you sell an average of 50 bags of coffee beans per day, and your supplier takes five days to deliver an order.

By using the most optimal reorder levels, businesses can keep storage and warehousing costs low to protect profits. Demands are not fixed, it’s volatile; You need to calculate demands based on trends. Economic order quantity (EOQ) is the amount of inventory that a business should order to minimize the cost of inventory and storage. This quantity is based on the company’s sales volume, production cycle, and the cost of inventory. Safety stock is a term used in inventory management that refers to a level of extra stock that is maintained to mitigate the risk of stockouts.

How automatic reorder notifications can make managing stock easier

It’s the secret ingredient to ensuring you always have just the right amount of stock at the right time without overfilling your storeroom, or worse, running out. This is where understanding and implementing the reorder point (ROP) in your inventory management becomes a game changer. We completely rewrote this piece to make sure we were giving you all the info you need to understand and use the reorder point formula. On the hand, too much stock can tie up capital, while too little can lead to disruptions in the supply chain. Now that you know the reorder point formula, we’ll show you how to find your reorder point by going through a sample calculation.

Deja una respuesta